Importance of Inventory Management

Inventory Management

Running a business, big or small, without a robust inventory

management system is next to impossible. If you don’t know the goods you

have in stock, you risk losing a sale or worse, the customer itself. A good inventory

control system is important for the visibility of goods, preventing stock-outs,

and having an idea of the value tied up in the stock at any given time.

What is inventory?

An accounting term, inventory refers to the goods in the process of

being sold to the customer. It includes raw materials, works in progress, and

finished goods. Hence, goods at every level are referred to as inventory. For

most firms, their inventory is their single biggest current asset and one which

is expected to sell within a year’s time.

Sell forecast

Sell forecast refers to the process of estimating how much sales

will take place in a future period. When these predictions are accurate, the

business can use them to make informed decisions. It also helps to predict

business performance in the short term and long term. A sell forecast relies on

a combination of factors – previous sale trends, the state of the industry and

other economy-wide parameters.

Sell forecasts are important because they enable a business to estimate how much inventory will be required to create a commensurate amount of finished goods to sell. Also, the business will have a more or less accurate idea of how much inventory to hold during the production process. Apart from having significant importance for inventory management, a sell forecast also helps the business to manage its cash flow and workforce.

Drawbacks of short inventory

Not holding enough inventory can result in significant losses for

the business:

i) Costly supplies

In case of emergency, not only will supplies have to be hastily procured, but the business will also have to pay any high price the supplier may quote. Being short on inventory reduces the bargaining power of the business. In addition, logistical costs will also rise if goods need to be shipped immediately -these are sunk costs that cannot be passed on to the final customer

ii) Supplier side risks

If a business has a limited number of suppliers, it is crucial to hold the right amount of inventory. If something affects the supply chain, production will not cease and the business will have time to hunt around for alternative sources

Drawbacks of over inventory

Some of the drawbacks which accrue to a business as a result of over

inventory are:

i) Warehousing costs

Storing too much inventory incurs higher costs related to renting

warehouse space, hiring labour to move stock around and transport costs

ii) Quality decline

Inventory held for too long may become obsolete. This is especially true in the case of consumer industries or food businesses. Consumer tastes change rapidly, and stocking up on too much of a particular good can result in significant losses

Art of optimization of inventory

Inventory is one of the largest areas where a business’s funds tend to be tied up. As such, to maintain an appropriate level of liquidity, it is important for the business to manage inventory at an optimized level. If a business has unsold inventory, it must regulate purchase levels to only hold the necessary amount at any given time.

Inventory loss management

Inventory loss can adversely impact your business’ profitability. The causes can range from rodent infestation to extreme moisture permeation to product expiry. Prevent your inventory from spoilage by monitoring moisture conditions in the warehouse, taking anti-pest measures, and selling products nearing expiry at a discount to avoid losses.

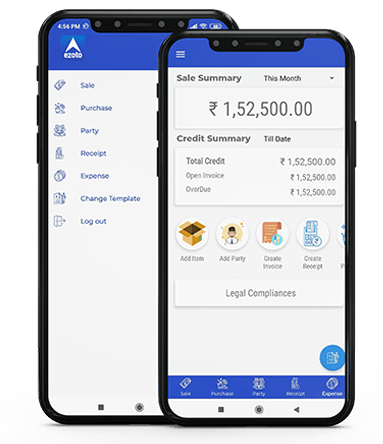

Use of tools for inventory management

For robust inventory management, invest in a reliable accounting software. EZO is a free accounting app for small businesses that has powerful inventory management features for optimizing inventory levels.

Use 80/20 rule for inventory

The 80/20 rule, when applied to inventory management, means that 80\\% of your storage space is only used on 20\\% of products - this rule can be used to optimize inventory management. If you’re experiencing storage issues, think about the space taken up by the 80\\% of products that don’t sell well. This means you must minimize the space taken up by such products and maximize space taken up by those that frequently sell. This is an effective inventory control system to maximize the value of your storage space.

Difference between a successful and failed business is inventory management

To run your business successfully without suffering losses, it’s

important you maintain just the right level of inventory. Register on LegalDocs

and start managing your inventory in an efficient and optimal way!

Knowledge Center

Knowledge Center

LEAVE A REPLY: